Located just a kilometre from the sea in Tyrendarra, Victoria, Radnor Properties is a 700-hectare dairy farm held in a family trust, set on sandy limestone soil. The farm, now managed by Martin Knowles, was purchased in 1996 by his parents, Bruce and Lyn, following their migration from New Zealand.

Martin grew up on the farm but initially pursued a career as a boilermaker and FIFO (fly-in, fly-out) worker before returning to his agricultural roots 15 years ago.

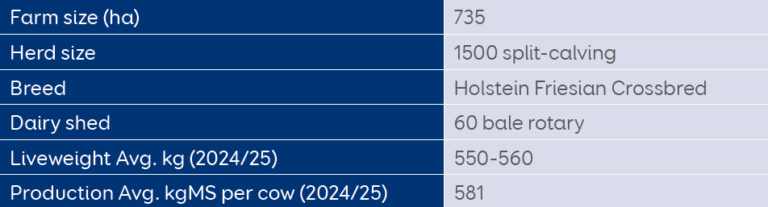

While Martin leads the day-to-day management, the farm is very much a collaborative family effort, with his siblings Kerry and Katie involved in areas like calf rearing and human resources. Today, Radnor Properties milks approximately 1,500 cows, primarily Holstein Friesians and crossbreds. The herd is split-calving and is milked twice daily in a 60-bale rotary system. The farm covers 500 hectares of dryland and 235 hectares of irrigated land, supported by a combination of pivot and fixed irrigation systems.

Performance genetics

Having predominantly used LIC genetics for over 20 years, the herd has consistently delivered impressive production. In recent years, each cow has produced milksolids roughly equivalent to her liveweight – around 570-580 kgMS per season. With payment based on milksolids rather than volume, this level of performance makes a strong contribution to the farm’s profitability.

Purpose-built facilities

A standout feature of the farm is its massive eco-shelter calving pad, and a brand-new, state-of-the-art calf shed, purpose-built with two separate sides to accommodate both autumn and spring born calves together.

The calving pad not only provides protection from harsh weather, but reduces stress, illness, and newborn calf losses.

Overall, it’s a well-designed setup that boosts efficiency, streamlines daily tasks like feeding, cleaning, and monitoring – and reduces workload during busy times.

A high-input operation, the farm is primarily pasture-based, supplemented with 2.5 tonnes of grain per cow annually. The feed pad diet includes silage and almond hulls, and during drought conditions, cottonseed and grape marc. The farm has faced two consecutive droughts, with the current year being particularly severe and marking the first time in 15 years without an autumn break.

Breeding strategy and trusted partnerships

When it comes to genetics, Martin doesn’t spend hours poring over catalogues or analysing every bull. Instead, he relies on a long-standing partnership with LIC and the trusted advice of his District Manager, Mike Waite.

This is where the use of a carefully selected team of bulls proves highly effective. Aligning with their breeding strategy – Holstein Friesian semen is used over the main herd, while crossbred semen goes into the heifers. The goal is to produce medium-sized cows that can walk long distances and perform well on the region’s often wet, heavy soils.

“Mike knows our herd really well, he understands our goals, and helps steer us in the right direction,” says Martin. “He’s become a key part of our decision-making process, working closely with us to develop the best breeding strategy suited to our system.”

The breeding plan involves two six week AI cycles each year. In the final two weeks of each cycle, the farm uses high BW, short gestation bulls to tighten calving.

Mike says “Keeping the right cow size has been really important, holding onto the Friesian influence without letting them get too big, whilst also using KiwiCross® semen for calving ease in the heifers.”

An interesting detail that adds to the farms complexity: Radnor Properties runs entirely on a generator, with no access to three-phase power.

Martin explains, “We’ve got two generators, so if one needs servicing or breaks down, we can just switch to the other. There’s plenty of capacity, so we never have to worry about overloading the system. In fact, it’s actually better than being on the grid. One big bonus is not having to stagger power use. For example, we can unload grain during milking, which wouldn’t be possible if we were relying on the grid.”

Team and technology

The farm employs 12 full-time staff, primarily from the Philippines, and use collars for monitoring cow health and heat. Herd testing occurs 4–5 times annually, with culling based on production, cell count, lameness, and reproductive results.

“When it comes to animals, the key is to grow them properly.” Martin explains, “We follow a ‘correct weight program’ through Warrnambool Vets, where calves are monitored and fed according to weight, until they are first joined.”

“This sets them up for life and handling them often in those early years leads to a better temperament once in the shed.”

Philosophy and advice

Martin’s philosophy is simple: “Farming is a learning curve. Take the good with the bad.”

His advice to fellow farmers is to breed according to their farming conditions, as he has found smaller, agile cows outperform larger Friesians.

Martin adds “If you’re like us with sandy soils or a wet farm, aim for smaller animals. Friesians can go lame and don’t get in calf.”

Farm facts